VisualODX helps CDD Conversion: Improving ECU Development and Test Efficiency

I. CDD Introduction

CDD file (CANdela Diagnostic Descriptions) is a diagnostic database file defined by Vector, Germany, describing the diagnostic service specification of ECUs and related para-meter format definitions, such as ECU identification, DTC, security levels, sessions, etc. It is mainly used for the development and testing of ECUs.

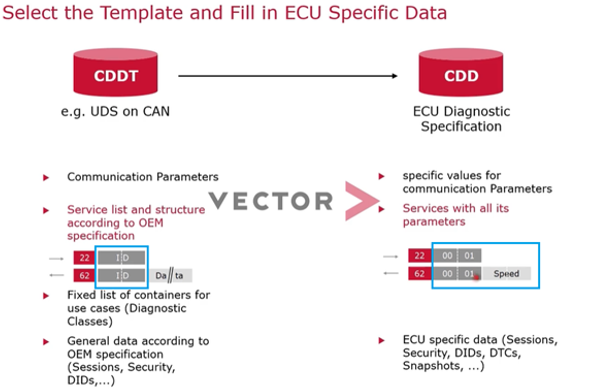

Usually we need to generate a CDD file based on CDDT and database editing; CDDT, i.e. CDD template, represents the OEM's definition of the vehicle diagnostic specification a-nd does not store specific parameter information.

(Figure 1: CDDT vs CDD content difference, source from Vector website)

The CDD file structure contains ECU information, Diagnostic Trouble Codes, Common Diagnostics/Base, Variants, State, Data Types and Negative Responses. Among them:

ECU Information: Define ECU address information, time parameters, etc.

Diagnostic Trouble Codes: Stores DTC information.

Common Diagnostics/Base Variant: Storage base diagnostic services as well as DID, RID, and failure parameters are defined.

Variants: Used for different phases or versions of the same controller, modified on the base diagnostic information.

States: Define the session mode, the security level and the corresponding switching state of the service.

Data Types: Defines the data type in the parameter.

Negative Responses: Defines the supported negative response codes.

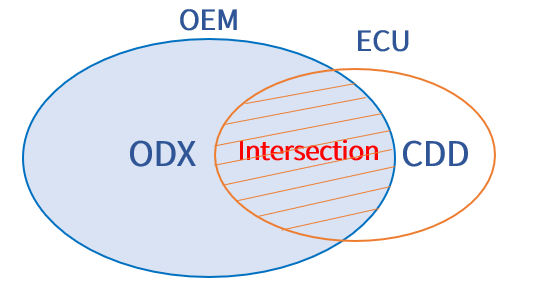

II. Comparison of the characteristics of the CDD and ODX formats

1. ODX is an international standard defined by ASAM and ISO, and the data format corresponds to the specification ISO22901-1; while CDD is a Vector private format.

2. ODX can package the whole vehicle ECUs into a PDX release, which is easy to manage and suitable for OEM, while CDD corresponds to one file for a single ECU, which is gen-erally used by suppliers for ECU development and testing.

3. ODX has the concept of layers, for example: -D stores the description of the whole vehicle ECU diagnostic information, -V is the vehicle topology definition, -F stores the Fla-sh file for flashing, and each layer inherits the data of the previous layer to avoid data redundancy.

(Figure 2: ODX vs CDD)

4. ODX is developed by the OEM and is suitable for the whole life cycle (ODX data structure is complex); while CDD is developed for ECU development and is suitable for the d-evelopment and testing phase (CDD data structure is simple).

5. ODX is open protocol, while CDD is private format.

III. Introduction to VisualODX

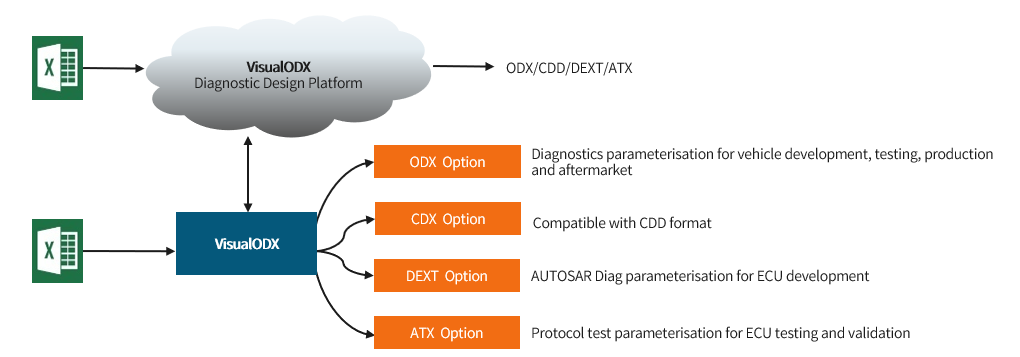

For the creation of diagnostic database, WINDHILL developed the diagnostic design tool — VisualODX, which can export diagnostic data with one-click by importing diagnost-ic questionnaires. Currently, it supports ODX/PDX/CDD/DEXT/ATXML files and mass data processing, which greatly improves work efficiency and accelerates development pr-ogress.

(Figure 3: VisualODX Product Families)

CDD export now supports all CDD properties and is available for tools such as CANoe, CANoe.Diva, DaVinci, CANdela Studio by Vector.

| Application Field:

• OEM diagnostic function development and debugging stage, diagnostic database construction and testing.

• Production department whole vehicle database creation.

• After-sales department creates diagnostic database, combined with diagnostic instrument to carry out after-sales inspection.

• ECU supplier diagnostic function development and testing.

| Software Advantages:

• Software customisation: semi-customisable software tools to support the expansion of customer-specific functions.

• Software support for floating version: floating version of the licence, without plugging the hardware dongle can be used, convenient for the use of off-site office team.

• Project Management: Innovative project configuration interface for easy project engineering management.

• Standard Excel template: User-friendly and quick to achieve the whole vehicle Excel questionnaire creation.

• Support multiple ECUs/diagnostic questionnaires import: Support single or multiple Excel import, unlimited number of Excel sheets.

• Supports exporting ODX/PDX/CDD/DEXT/ATXML files for a single ECU or all ECUs.

• One-click check: follow the ASAM standard ODX templates, Excel templates combined with double-checking to effectively ensure that the generation of data integrity, accu-racy. Support for analysing and locating error messages.

• One-click conversion: automatically generate ODX/PDX/CDD/DEXT/ATXML files.

| Software Features:

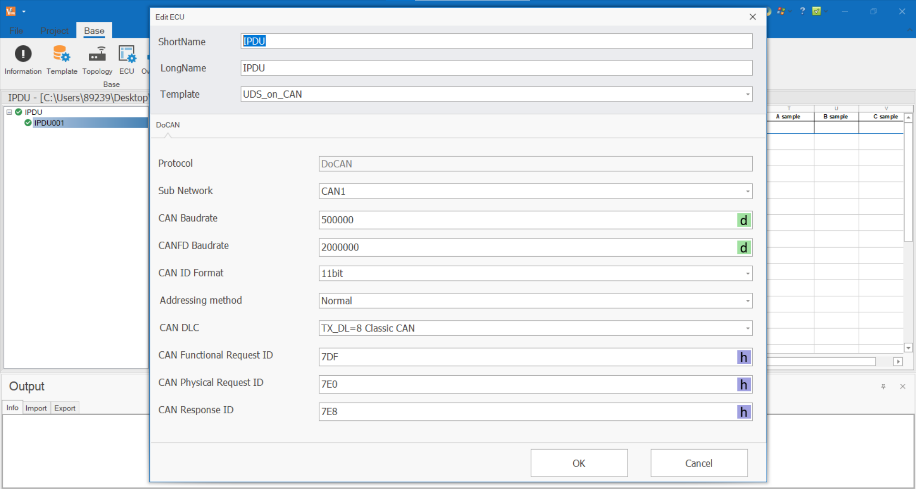

1. Add ECU information: Support to add information of multiple ECUs for the project, the number of ECU is not limited.

(Fugure 4: ECU Configuration)

2. Add ODX Template: Import customised ODX templates for projects.

(Figure 5: ODX Template Import)

3. Import Excel: Click Link to import the Excel sheet. Multiple EVs can be added to the ECU and the number of EVs is unlimited.

(Figure 6: Import Excel)

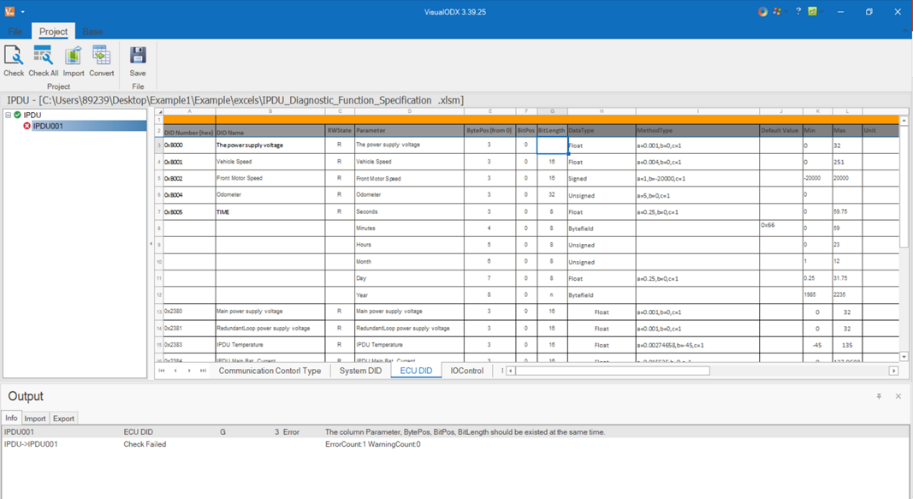

4. Consistency checking: The errors are displayed in the Output area below, and double click also allows error location.

(Figure 7: Consistency Checking)

5. Convert Function: Convert ODX/PDX/CDD/DEXT/ATXML files. Not only support for exporting files for individual ECU, but for exporting for multiple or all ECUs in a project.

(Figure 8: Convert Function)