OTX script development, simulation and debugging with Q-Studio

I. Backgrounds

Nowadays, with the rapid increase in the number of electronic devices and software in vehicles, more and more complex ecu testing is required in the vehicle development, production, testing and after-sales phases, showing an exponential growth trend. In the past, the commonly used manual test methods have been completely unable to meet today's testing needs, thus promoting automated testing has become particularly important.

However, the diagnostic test sequences produced in other formats or programming languages such as Java, C++, etc. cannot achieve the unity of specification, format, implementation, execution, etc., and cannot exchange smoothly between different departments, which affects the work efficiency and is even more difficult to manage, and is no longer adapted to today's fast-paced and complex development environment.

II. Full automation testing by developing OTX scripts

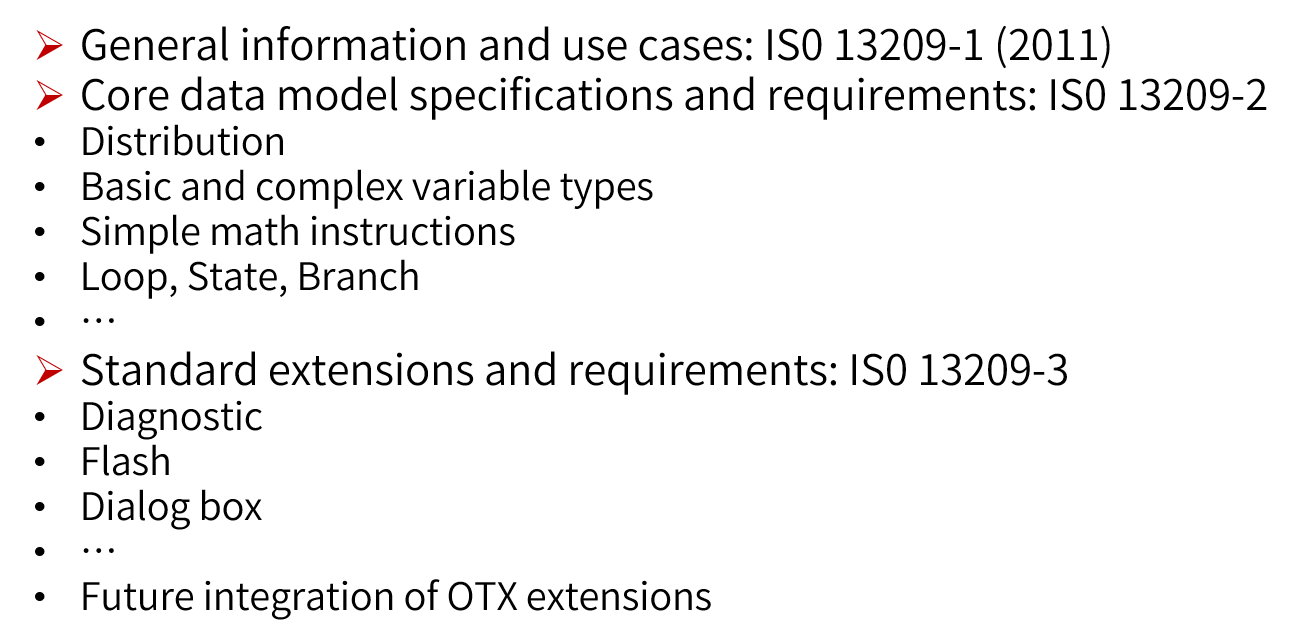

Facing various complex application scenarios, based on IS0 13209 standard, WINDHILL has developed a tool to realize the development, simulation and debugging of OTX diagnostic and test sequences — Q-Studio, which is designed to be used in the development of ECU and vehicle test scripts, and to support the diagnostic data according to ODX 2.2.0. OTX scripts developed by Q-Studio are fully compliant with ISO international standards, and it does not depend on specific software tools, those OTX scripts can be exchanged and circulated directly between different departments, so as to achieve the unity of specification, format, implementation and execution. In addition, OTX scripts are highly reusable and can be reused in different projects according to requirements, which greatly improves testing efficiency.

(Figure 1 OTX Standard)

III. Q-Studio — Visual editing tools

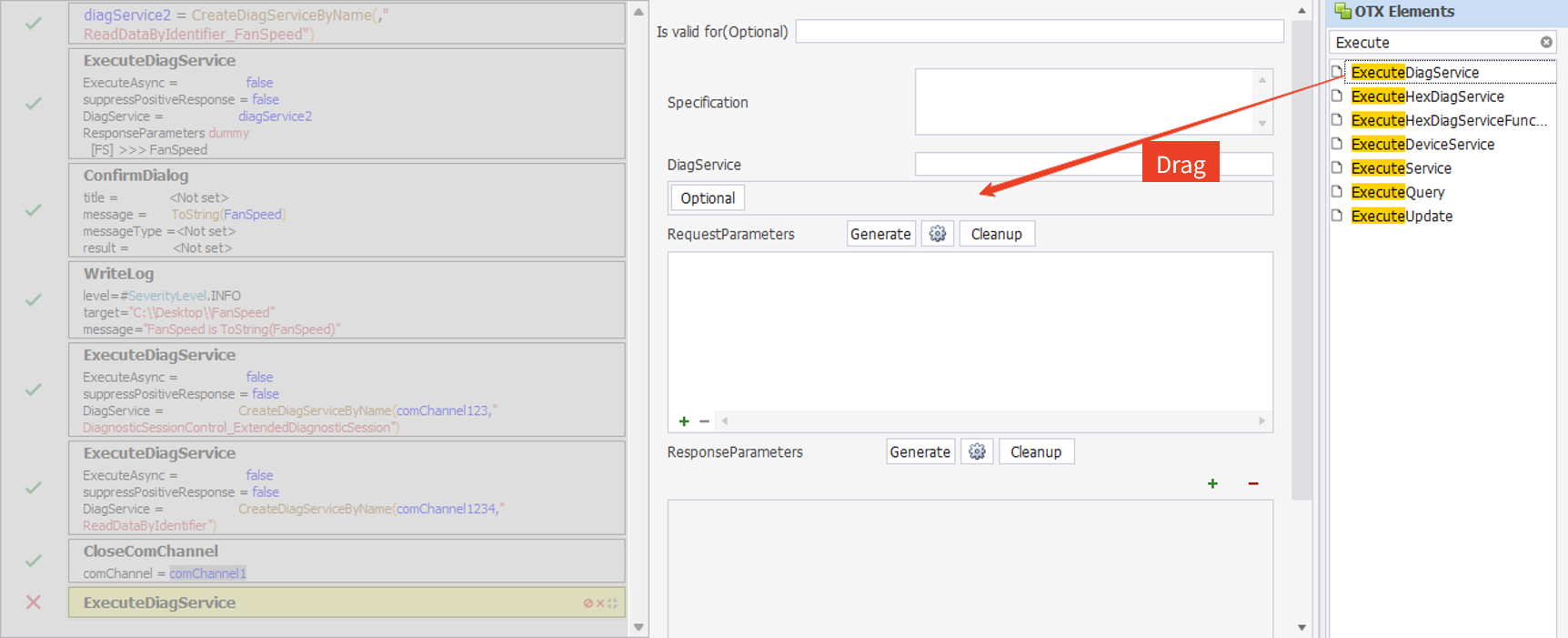

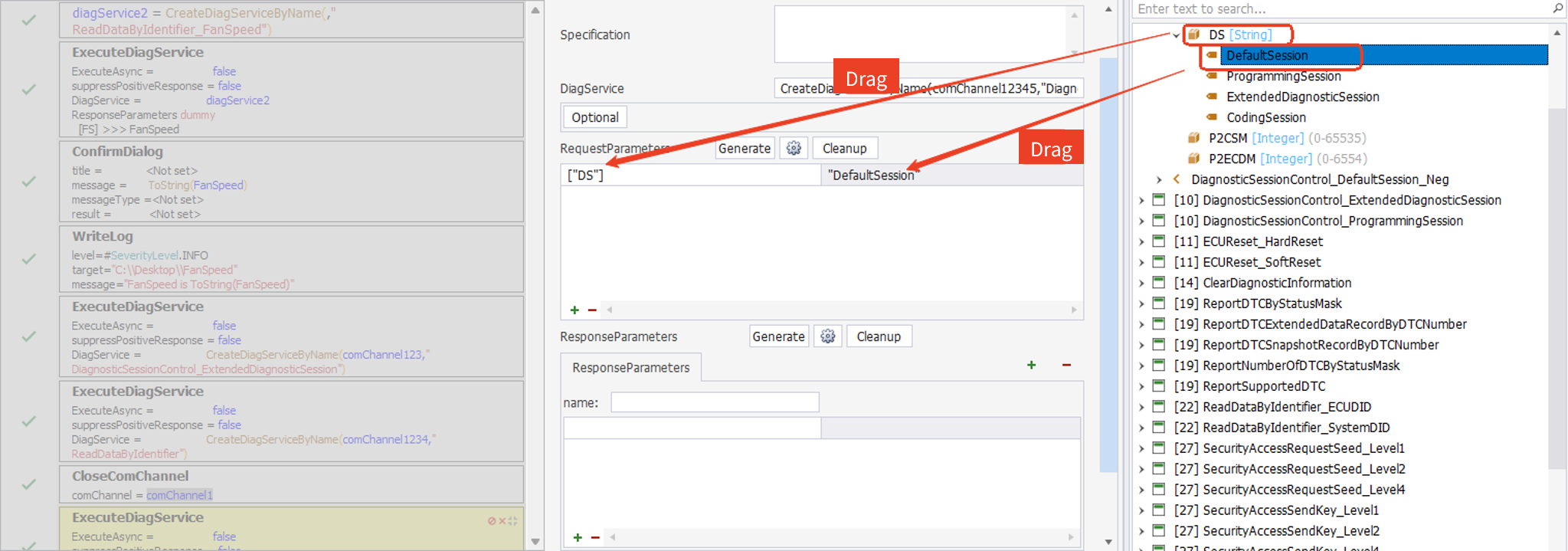

Q-Studio complies with the OTX function of ISO 13209 and all parameters in the database have been modularized. Therefore, when using Q-Studio, users only need to drag and drop the functions, services and parameters to the editing window according to the diagnostic test specification cases, and then complete the development of a script, which greatly reduces the difficulty of writing sequences.

(Figure 2 Schematic diagram of drag and drop editing of OTX function)

(Figure 3 Schematic diagram of ODX database visualization editing)

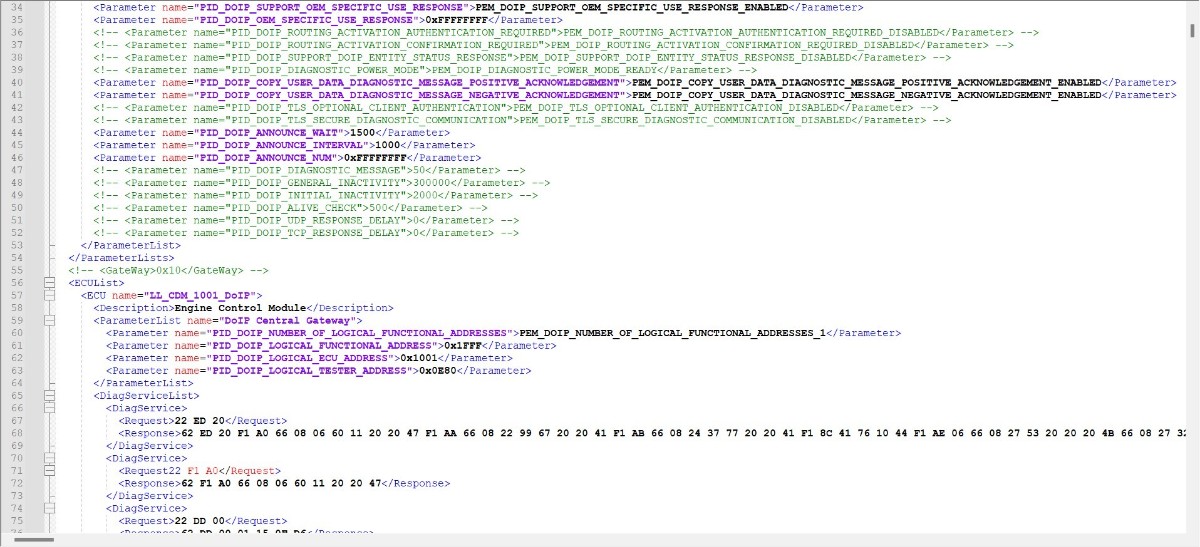

As a simplified programming language, what the written OTX sequences can accomplish depends entirely on the content of the scripts written by the diagnostic test engineers, and the resulting OTX format files are independent of ODX and the different D-Servers.

(Figure 4 Script schematic diagram)

IV. Introduction to OTX sequences simulation

As the workload of in-vehicle testing rises dramatically, the accuracy of diagnostic test scripts cannot be ignored. For this reason, combined with the D-PDU-API interface developed by WINDHILL in line with international standards, we have introduced the virtual car technology, which can realize the simulation of diagnostic scripts and ensure that there are no grammatical errors in the OTX scripts at the stage of developing.

Then how do users realize the simulation in Q-Studio? Simply configure the corresponding PDX database file, and then import the simulation file template of WINDHILL. Configuration operation is simple, and can meet most of the simulation needs.

(Figure 5 Schematic diagram of PDX file configuration)

(Figure 6 Schematic diagram of simulation file configuration)

In terms of producing simulation data, WINDHILL has customized the diagnostic service simulation file, which can freely define the diagnostic request and the corresponding response, with the function of response strategy definition.

(Figure 7 Schematic diagram of diagnostic service simulation file)

V. Introduction to OTX sequences debugging

As shown in the following figure, select the location where you need to add a breakpoint, right-click the function, and click Switch Breakpoints to set the breakpoint.

(Figure 8 Schematic diagram of breakpoint setting)

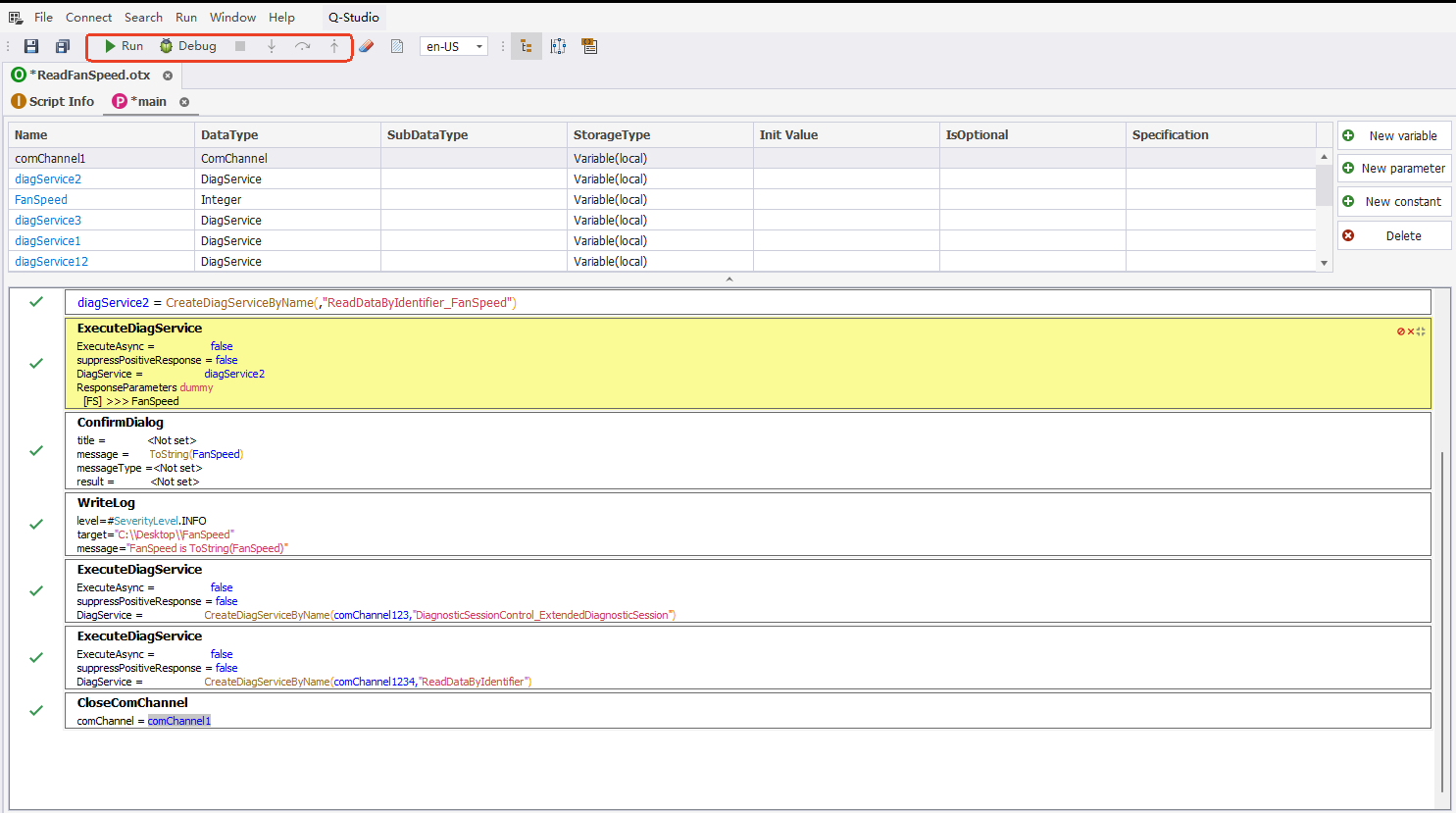

After starting the simulation, there will be a row of debug buttons below the navigation bar of Q-Studio software for debugging scripts. Click the Run button to start the sequence debugging. If you set a breakpoint in the sequence, it will stop at the breakpoint; if you click “Stop Debugging”, it will abort the debugging; If you click the “By Statement” button, you will debug down a sequence; if you click the “By Procedure” button, you will debug the procedure one by one; if you click the “Jump Out of Current Function” button, you will jump out of the sequence of the function you are currently debugging.

(Figure 9 Schematic diagram of debugging function buttons)

VI. Execution of OTX scripts

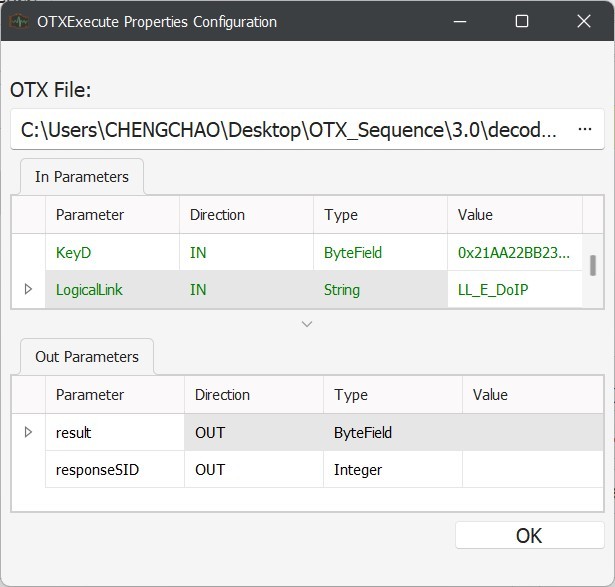

Q-Tester.Expert is an engineering diagnostic instrument based on ODX (ASAM MCD-2D/ISO 22901-1) international standard developed by WINDHILL, through which can realize the data interaction with ECU controller. In this software, we embedded OTX RUNTIME, which can parse the functions in OTX scripts, execute OTX scripts, and combine the diagnostic function of the diagnostic instrument to realize the information interaction with the controller.

(Figure 10 Schematic diagram of OTX script loading interface)