Precise Acquisition of Proportional Valve Current for Construction Machinery:IPEhub2+ Proportional Valve Shunt Meter for PWM Filtering & Remote Monitoring

Since the implementation of "The Belt and Road" and "New Infrastructure" Program, the demand for construction machinery has shown a trend of rapid growth, and for the construction machinery, its proportional valve control issues cannot be ignored. The proportional valve is a new type of hydraulic control device - in the ordinary pressure valves, flow valves and directional valves, proportional solenoid to replace the original control part, and according to the input electrical signal continuously, proportionally to the oil pressure, flow or direction of long-distance control.

Problems Facing

An ordinary shunt meter is made according to the principle of voltage difference is generated at both ends of a resistor when a direct current passes through it, and it can only measure DC current in a straightforward manner. The current of the proportional valve of construction machinery is PWM current signal, which needs to be filtered by special methods, so it is obvious that the common method of measuring current is no longer applicable. Therefore, how to measure the current of the proportional valve is very worth pondering deeply.

Construction Machinery Proportional Valve Current Measurement Method

Brief Introduction

Electro-hydraulic proportional valve is a control element that appeared in recent years, it is the input electrical signal continuously and proportionally control the flow, pressure and direction of the control valve in the hydraulic system, is a hydraulic control element between the ordinary valves and servo valves. Electro-hydraulic proportional valves have the following characteristics compared with ordinary hydraulic valves:

• Remote or programmed control can be achieved relatively easily;

• It can continuously and proportionally control the pressure and flow of the hydraulic system of the shearing machine, and realize the control of position, speed and force to the executive element, while also reduce the hydraulic flushing during the pressure change;

• Reduces the number of hydraulic components in the system and simplifies the oil circuit;

• Proportional valves are generally pressure-compensated, so their output pressure and flow rate can be unaffected by load changes.

In general engineering technology only need to control force, displacement, speed and other parameters, because the dynamic performance requirements are not high, so electro-hydraulic proportional valves can meet the requirements, therefore, it has been widely used.

The core of electro-hydraulic proportional control is the control current. The current from analog control power output stage to the proportional valve coil is continuous, high power consumption, and need to install a heat sink. The PWM control power output stage for the switching structure, low power consumption; PWM signals contains the same frequency pulsation, without the need to install another flutter signal, and have strong interference and contamination resistance, short lag time, and high repeatability accuracy. In addition, due to the use of digital control, its connection with the computer is very convenient, and program control can be realized.

Solution

The solution of WINDHILL is to use proportional valve shunt meter to measure the valve current, and output the voltage signal. The module is equipped with PWM filter inside, which can convert the waveform of PWM current signal into stable voltage signal and output it to the analog module, meanwhile, the remaining channels of the analog module can collect other sensor signals, then connect to IPEhub2 to collect the signal of the construction machinery vehicle bus, and output it to the PC. Afterwards, the data can be remotely viewed in real time by using the IPEmotion APP.

In the field of test scenes or construction machinery with harsh working conditions, the testers in the test environment not only have no protection for their own safety, but also affect the test process, such as high-temperature and high-pressure testing, testing of hydraulic systems of construction machinery, etc. The combination of IPEhub2 and IPEmotion APP not only protects the testers, but also eliminates the factors that have an impact on the results of the test. There is no doubt that it is an excellent solution for such experiments.

(Diagram of equipment connection)

Hardware Support

Proportional Valve Shunt Meter

The module is used to measure current and output a voltage signal. The module has an internal PWM filter that converts the waveform of the PWM current signal into a stable voltage signal output, and it has high compatibility with IPE modules.

Performances

• Working temperature: -40~85℃;

• Electrical isolation: not isolated;

• Supply voltage: 15V;

• Sampling resistance: 100mΩ;

• Acquisition current range: 0~2A;

• Sampling accuracy: ≤0.5%;

• Output signal: 0~1V.

Analog Acquisition Module

Performances

• Supports analog measurement;

• 8-channel analog signal input;

• Sampling rate up to 5kHz, channel power supply: 0~15VDC/±15VDC;

• Measuring range: ±10mV~±100V (voltage), 0~±20mA (current);

• Measurement accuracy: ±0.025% (voltage), ±0.05% (current);

• Hardware filtering: 600Hz;

• Protection level: IP67;

• Relative humidity: 5~95%;

• Configuration interfaces: CAN /CAN FD;

• Working voltage: 6~59VDC;

• Working temperature: -40~125℃.

IPEhub2 & IPEmotion APP

Performances

• Interface: 2 CAN HS;

• Protocols/Messages, add CCP/XCP on CAN; J1939; OBD; UDS/ODX/PDX;

• Data storage SD card supports up to 32GB;

• Ethernet interface: 100 Mbit;

• Remote function: Wi-Fi;

• Data storage file format: ZIPRT, MDF4.1;

• Power supply: 9~36VDC;

• Full electrical isolation;

• Protection level: IP54;

• Working temperature: -40~85℃.

Software Support

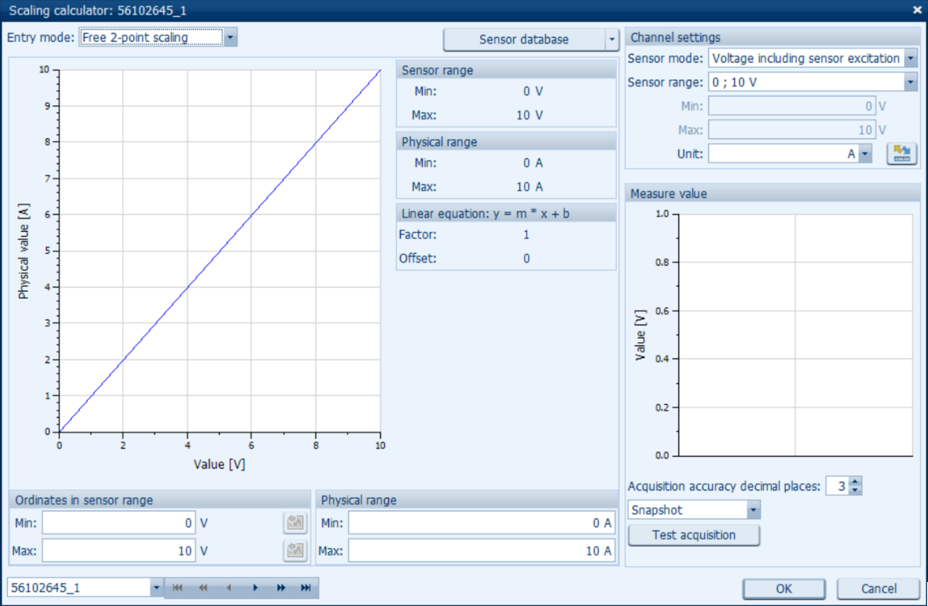

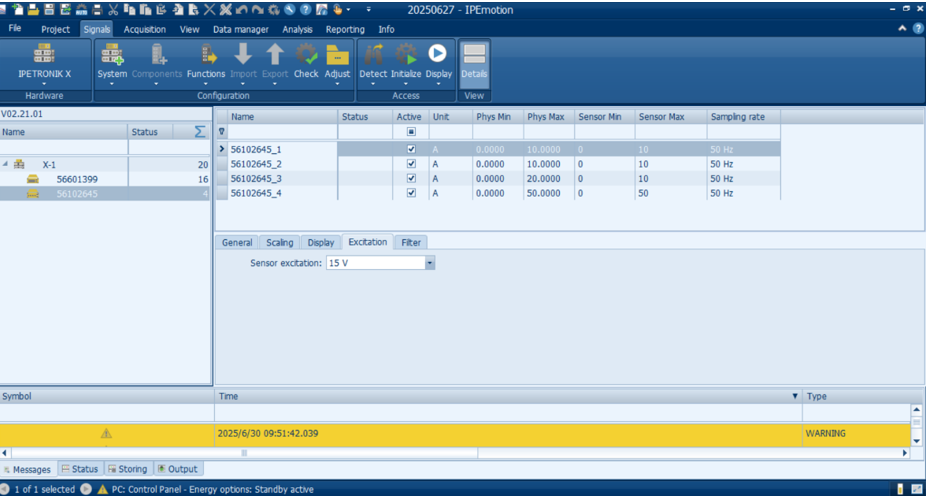

Turn on the power and detect the IPEhub2 through Ethernet cable or Wi-Fi, after detecting the analog module, channel 1 is connected to the proportional valve shunt meter, and then set the proportionality relationship of 0~2A corresponds to 0~1V, and the sensor range is 0~1V, and it is also necessary to supply power to the proportional valve shunt meter. In this way, the proportional valve current and other sensor signals can be measured and collected simultaneously.

(IPEmotion configuration interface)

Previous Updates

▶ Real-time Energy Consumption monitoring solution for EV Charging Piles

▶ What kind of data logger can shorten the whole vehicle development cycle?