Accelerate Vehicle Development - WINDHILL Road Load Data Acquisition (RLDA) Test Solution

1 Background

Before a car is launched on the market, it is very important for vehicle manufacturers to understand the load that the product can withstand. Therefore, Road Load Data Acquisition (RLDA) tests need to be conducted. By obtaining the load information of the vehicle traveling on the actual test field or highway roads, it provides target signal input for the vehicle bench road simulation test, as well as for design and simulation analysis used in vehicle development. Under various enhanced road conditions, the load conditions of key components are collected to verify the reliability of the components.

Challenges

• There are many devices and the installation is difficult;

• Data acquisition is not synchronous;

• The data sampling frequency is high;

• Difficulty in data storage;

• Data needs to be transmitted over long distances;

• Data analysis is cumbersome;

• The test environment is diverse.

The RLDA test requires the collection of data such as pedal force, ICP (IEPE) vibration sensor, strain, video, temperature, GPS, displacement and vehicle bus under actual road conditions. The corresponding sensors are as follows:

(Figure 1 Examples of Sensor Types)

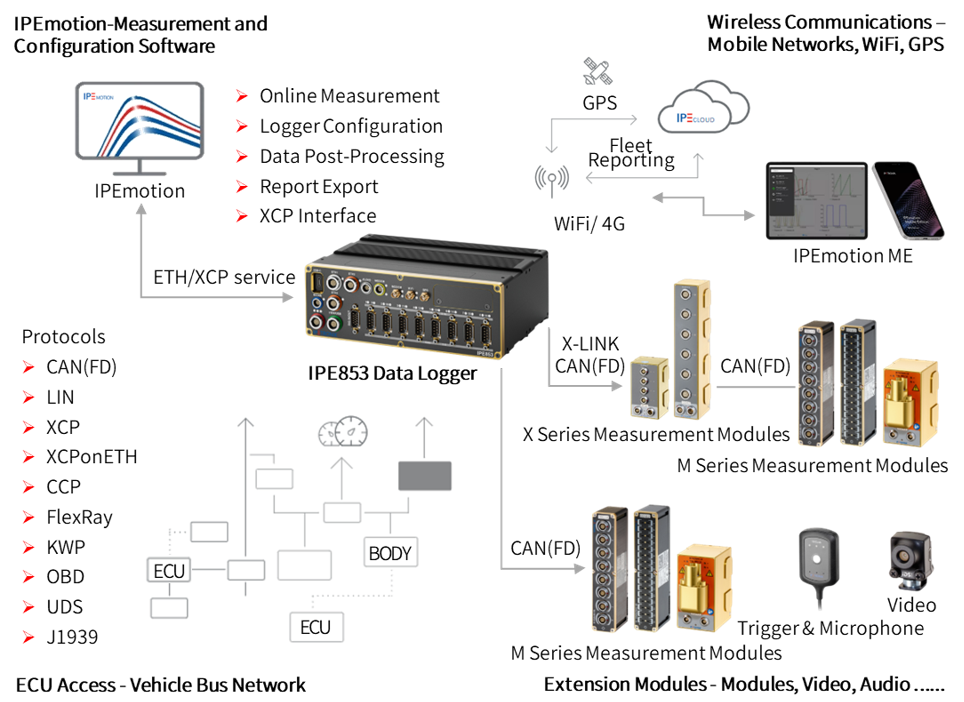

2 Solution Overview

IPETRONIK can provide acquisition modules, data loggers, data acquisition and analysis software, as well as sensor devices. The test system is shown in the following figure. The single-channel sampling frequency of the measurement module can reach up to 400kHz, and it supports Ethernet connection with the data logger IPE853. The IPE853 can synchronously collect various signals and store data. It can also display the collected data in real time through wireless communication, mobile phones or monitors. Meanwhile, the test data can be uploaded to the server via WIFI or 4G communication.

(Figure 2 Data Logger Syetem Overview)

Hardware Support

Mx-SENS2 FAST: A 4-channel analog measurement module for collecting signals with a high sampling rate. The sampling frequency of a single channel can reach up to 400kHz. Support the acquisition of voltage, current and IEPE signals.

(Figure 3 Mx-SENS2 FAST)

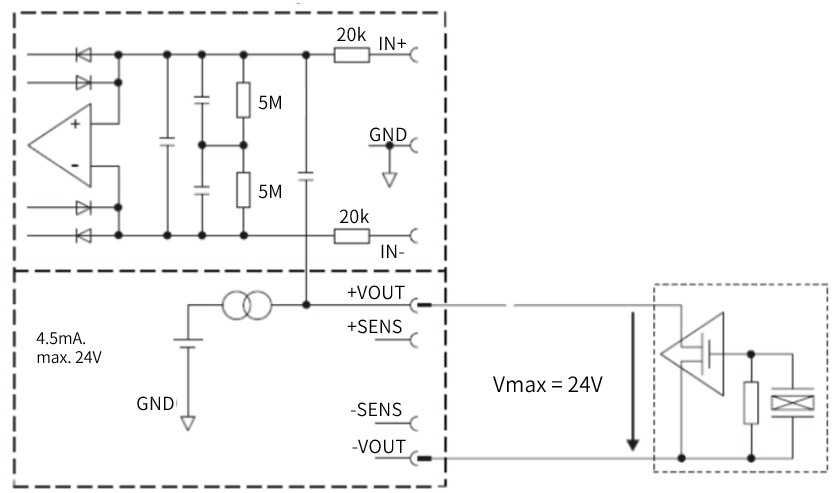

The IEPE acceleration sensor will be used in the RLDA test. IEPE (Integral Electronic Piezo-Electric) refers to an acceleration sensor with a built-in electrical quantity amplifier or voltage amplifier and is powered by a constant current voltage source. One of the major advantages of the IEPE sensor is its excellent signal quality, low noise, strong resistance to external interference and long measurement distance. In addition, IEPE sensors need to be used in conjunction with measurement modules that support IEPE to function properly.

(Figure 4 The Connection Principle Diagram between the Measurement Module and the IEPE Sensor Cr. IPETRONIK)

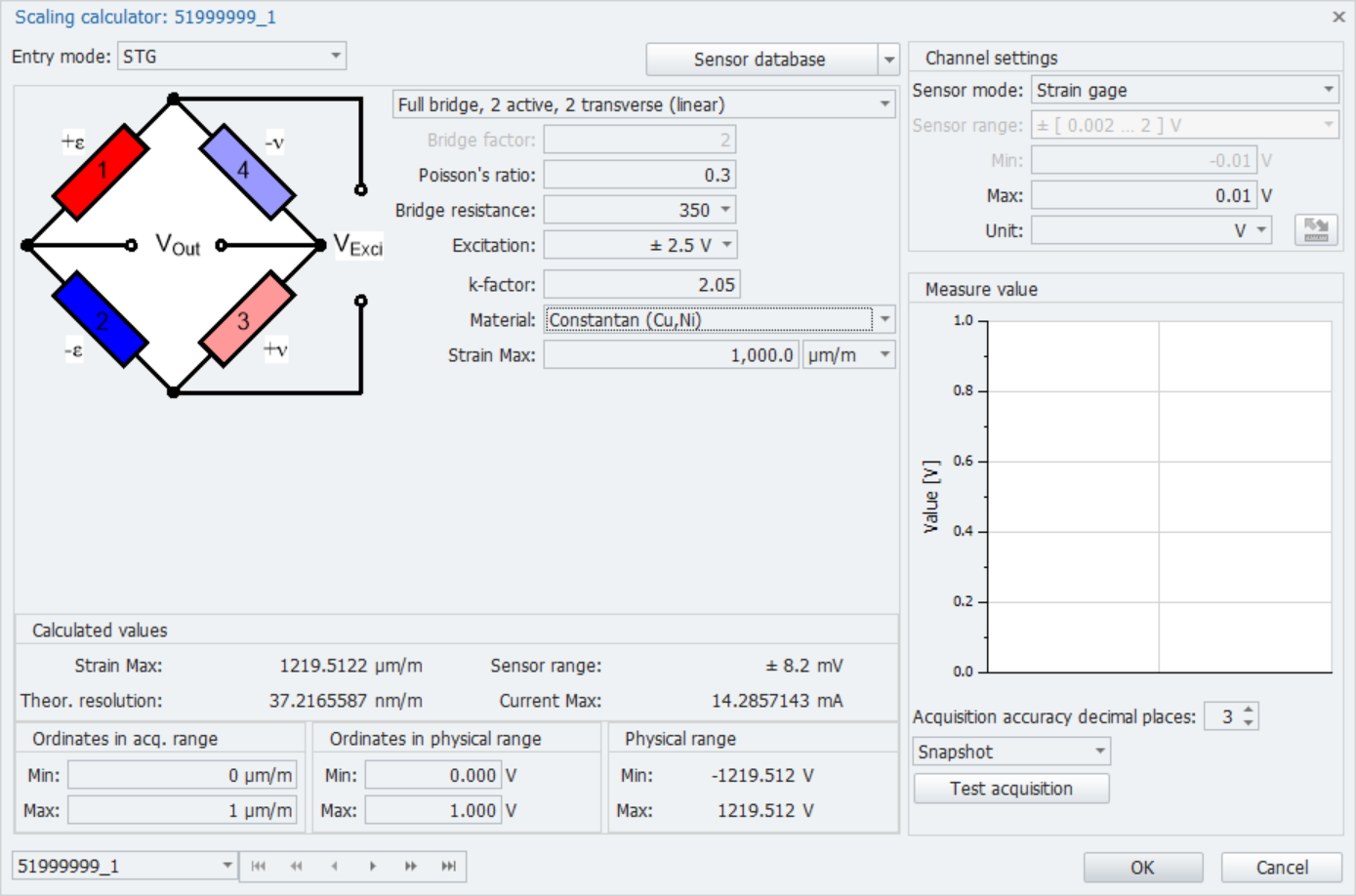

Mx-STG2 6: 6 channel signal input, the sampling rate of a single channel can be as high as 100KHz and Ethernet communication. The STG mode not only supports bridge-path compensation and shunt inspection, but also supports different channel sampling rates, and can select each measurement input to power the sensor.

(Figure 5 Mx-STG2 6)

The RLDA test requires the collection of strains of components such as axles and drive shafts. The strain bridge modes of the STG measurement module include 1/4 bridge, half bridge and full bridge. It selects the corresponding strain bridge according to the connection of the actual strain gauge. IPEmotion can configure the STG module and select STG (strain gauge). By selecting the corresponding strain bridge, parameters such as bridge resistance, excitation, K factor and maximum strain can be configured, and the scaling relationship between strain and output physical quantities can also be configured.

(Figure 6 Example of STG Measurement Module Scaling)

Software Support

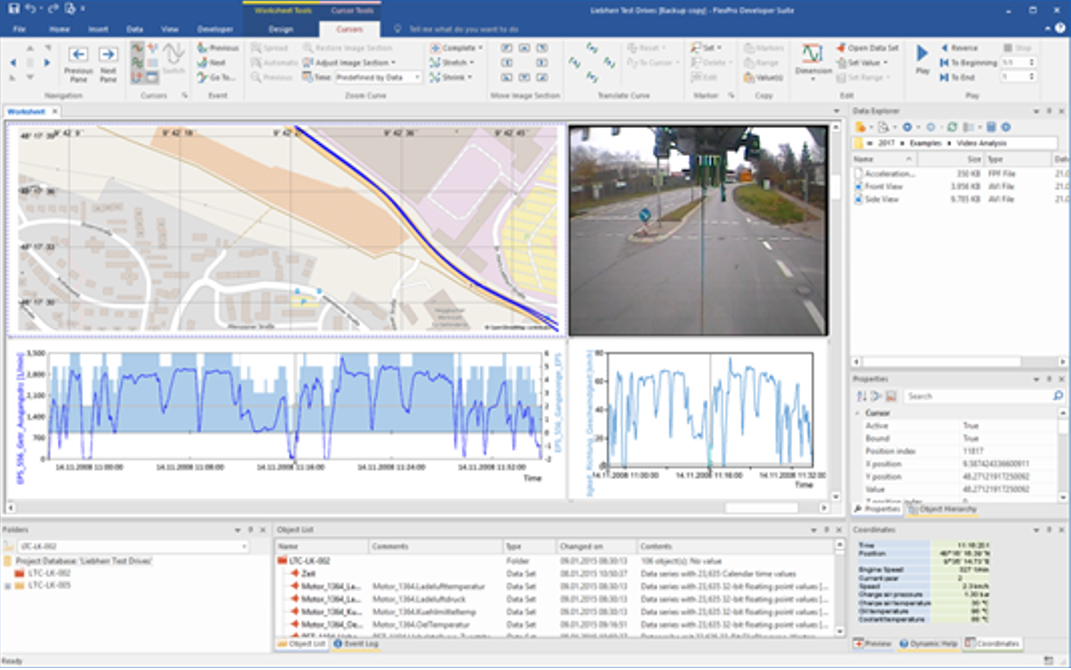

FlexPro software is a powerful, intuitive software that can be used for analyzing and displaying data, especially excelling in analyzing dynamic processes. Its functions are very powerful in terms of data management, analysis and display. This software not only supports almost all well-known data acquisition and signal test data formats on the market, but also can export data in multiple formats, featuring excellent openness. It can also save report templates, import measurement data and generate analysis reports with one click, which is very time-saving and efficient.

(Figure 7 FlexPro Software Analysis Interface)

Previous Updates

▶ What Kind of Data Logger Can Shorten the Whole Vehicle Development Cycle?